Products

TFOC Products line

EFLEX

EFLEX Underground Flexible Plastic Conduit. For : Underground Electrical Conduit Installation : EFLEX offers a range of merils not shared by conventional conduits such as Steel and PVC pipes.

EFLEX Is Available in Many Sizes

Ranging from 30 Ø to 150 Ø

Ready to Be Delivered upon Request

The standard dimensions of EFLEX are as shown in the table below. A pilot wire is provided inside EFLEX in the course of its production. It is connected with the cable pilot wire to pull the cable in to the pipe. EFLEX is, as a rule, shipped from the factory, wound in a coil. A pilot wire has an allowable tensile strenght of 50 kg.

Table of Standard Dimensions

• When purchasing EFLEX, it is recommended that its nominal diameter be more that 1.5 times as large as the outer diameter of the cable to be accommodated.

• Dimensions other than the above standards are acceptable, but requests for longer dimensions cannot always be met due to transportation considerations.

PROPERTIES OF EFLEX

•Product Characteristics

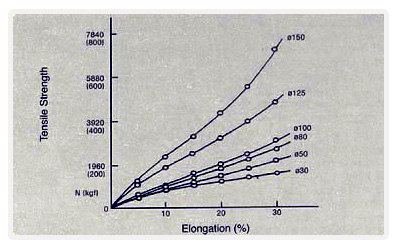

Tensile Strength

When EFLEX, both ends of which have been specially processed with terminals, is stretched axially, it displays tensile strengths for different sizes as shown in the right Figure. When released from an approximately 40% elongation, EFLEX returns to its original state without retaining any permanent strain. In addition, its joints demonstrate the same strength as its main body.v

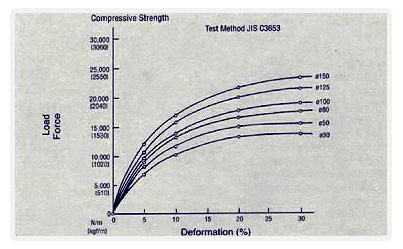

Flat-compression Characteristics

When compressed between two parallel plates as shown in the sketch below, EFLEX

displays the relationship between load and elongation according to size as shown in the right Figurev.

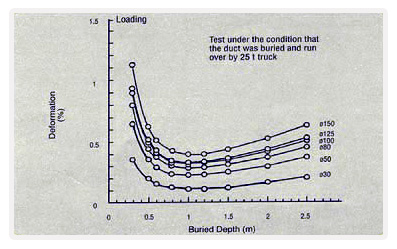

•Load-withstanding Strength

For this, EFLEX was buried 1.2 m under the ground and was run over by a truck. The flattening deformation was measured that EFLEX was scarcely affected, demonstrating sufficient strength.

Cable Conduit Model

A model for a manhole and outdoor rising terminal is shown below.

For EFLEX , the following 16 parts or related products are available. Select the appropriate products in accordancd with purposes.

| Parts and Related Products | Purpose | Type |

1. | Straight joining materials | For joining EFLEX units together | For EFLEX sizes |

2. | joining materials for EFLEX to together | For joining EFLEX units other pipes | Various in accordance with mathod pipes |

3. | Bellmounth | For finishing manhole wall | For EFLEX sizes |

4. | Waterproof cap | For closing the openingsof spare conduits | For EFLEX sizes |

5. | Bellmounth with cover | To prevent sand from entering spare conduits | For EFLEX sizes |

6. | Waterproof wall sealing compound | For sealing manhole walls against water | Two-agent type |

7. | Waterproof materials for EFLEX in manhole (Sand Preventive) | For waterproof treatment of manhole walls | For EFLEX sizes each for single and for multiple cables |

8. | Outdoor end treatment(Sand Preventive) | For waterproof treatment of rising terminals | For EFLEX sizes each for single and for multiple cables |

9. | Buffer materials | For reinforcing the outside of manholes | For EFLEX sizes |

10. | Clamp | For security of terminal boxes | For EFLEX sizes |

11. | Universal band (commercially available) | For security of terminal boxes | For 50 mmØ or less and for 80 mmØ or up |

12. | EFLITE | For security of electrical poles | 20 mm think, 300 mm wide and 1700 mm long |

13. | Sign tape | For Preventing damage during-trenching | 0.15 mm think, 150 mm wide and 50 m long |

14. | EFLEX | ||

15. | Rising end protector (commercially available) | ||

16 | Other pipe |

Accessories of EFLEX

- Bellmouth with cover

For preventing sand from entering spare conduits

- Waterproof cap for EFLEX End

- Straight Joining Part (for joining the EFLEX system together

- EFLEX Clamp

If EFLEX units are fitted to a terminal box

- Waterproof Material for EFLEX Used in Manholes and Riser

- Joining EFLEX to Other Pipes

STANDARD METHOD FOR LAYING EFLEX

EFLEX, Long and Easy to Bend, Facilitates Installation and Saves Installation Time for Cable Conduits

EFLEX, If used as a cable duct, should be laid in accordance with all items prescribed in the Electrical Equipment Technique standard and all other applicable laws and regulations. At the construction site, therefore, EFLEX should be laid in accordance with the standardized laying procedures described below.

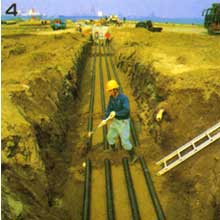

Laying

Arrangement straightening sand filling

Trenching

EFLEX, The trenching width is determined by the number of EFLEX laid. However, the width should be determined according to considerations of economy and safety associated with the laying operation-it is necessary to follow all safety procedures so that landsides do not occur at the minimum width. The lower-most EFLEX should not be laid directly on rocks and pebbles It is recommended that the excavated area should be leveled and then covered with sand before laying EFLEX.

EFLEX should be laid carefully so as to prevent soil, sand and water from entering it through the end mount. If the EFLEX delivered to the site is wound in a coil, it should be laid in accordance with the following procedure. The coiled EFLEX should be rolled along the trenched ground, held by 3 or 4 laborers to avoid deformation. In laying EFLEX, it is necessary to roll its coil along the crute, If pulled along without rolling, EFLEX will twist as every turn of the coil is stretched straight. When 2 or more EFLEX are to be laid in parallel, the respective EFLEX should be arranged with the specified distance as shown in Fig A. To this end, a simple guage shown in Fig B. should be prepared to straighten the laid EFLEX every 3 or 4 maters. The straightened EFLEX should then be held in place with sand or the equivalent, and the guage should be removed. EFLEX should not be laid in pipe saddles which have been used for conventional Hume pipes.

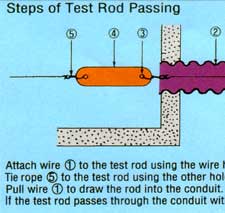

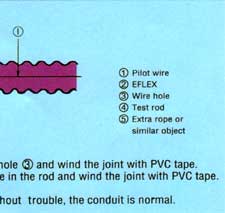

Passing test rod

When laid completely, EFLEX should be checked for straightening and internal void. Test rods should be selected according to the size of EFLEX, Passing of test rod is recommened in provisional burying and when EFLEX systems are laid completely.

Filling

Cable pulling-in

After conduits are checked for void by passing a test rod through them, fill in the trench to complete the laying

Cables should then be pulled into the EFLEX by utilizing the pilot wire previously accommodated in the EFLEX.